C7 Corvette Gets the Singular Treatment

This C7 Corvette was brought to us for an aero improvement. It was already quick thanks to a good chassis and lots of power, but there were a few areas where there was lots more performance to easily extract.

Wing

The car came to us with an authentic C7.R wing (let’s not ask how he got it!). But even a wing like this can be improved. The endplates were comically small, because IMSA restricts the endplate size for their series. Why? Because they know how significant endplates are for wing performance. Since this wing’s new home is on a time attack car with no such restrictions, we could greatly improve the wing’s efficiency with a simple endplate upgrade.

Singular Endplates – For many popular wing models

Making more downforce at the back is relatively easy with a wing. But that needs to be balanced with the front. And one of the often overlooked ways to improve front downforce is to reduce lift. Less lift is more downforce. As speed increases, turbulent air pressure builds up in certain areas and acts on the surrounding surfaces. A small amount of pressure spread over a large surface area can amount to a surprising amount of force, and at high speeds there’s a lot of pressure built up.

Common high-lift areas at the front of the car are inside the engine bay and front wheel arches. So we tackled both.

We began with tuft and pressure testing the existing car to identify the most effective locations for vents.

Fender Louvers

Based on the data collected, we designed a set of fender louvers for the C7. These are ideally placed to extract the most pressure from the wheel wells, which reduces lift and also improves brake cooling.

Singular C7 Fender Louvers – More details here

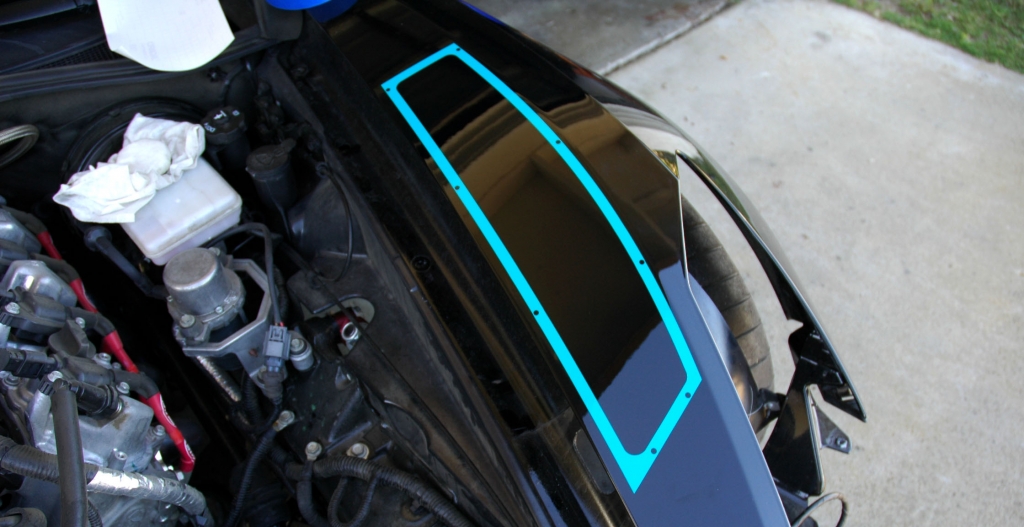

Hood Vent

The C7 has a well designed hood vent, and like the C7R wing at the back, we looked to improve the performance by enhancing the effectiveness of what was already there. We designed a gurney flap that mounts to the existing opening. This flap pushes air coming over the hood upwards just ahead of the vent, which creates a larger low pressure zone over the vent opening. The lower the pressure at the vent exit, the more air it extracts. That means more air is being pulled through the radiator and out of the engine bay, and that means better cooling and reduced lift (in other words, more downforce).

Singular C7 Carbon Fiber Hood Gurney Flap – More details here

The combination of fender louvers and center vent gurney make for a striking visual. But most importantly, it all works as good as it looks.

Splitter Endplates

One final addition to improve front grip was still on the menu. This car had a decent splitter already, which was making good downforce. But the details of a splitter really make the difference. A traditional splitter makes the largest amount of downforce around the center, and the pressure on the splitter fades as the air works its way sideways and spills off the side of the splitter ahead of the front wheel arch. To recover some of this lost downforce, we made small endplates for the splitter sides. These triangle shaped vertical pieces are simple things, but make a big difference in total downforce on the splitter.

Interestingly, Chevy went this same route with their Z07 track package; vertical fences on the outside corners of the splitter to improve downforce, nearly identical to the ones we came up with. Because, well, it works.

With the additions of the wing endplates, fender louvers, main vent gurney flap, and splitter endplates, this C7 is making more downforce than ever, and enjoying better cooling. And that means more grip and lower lap times.

Immediately following these updates, this car went on to take numerous 1st places in class over the following race season!

No comments yet.